Introduction

In the bustling landscape of international trade, factory audit services in China have emerged as a crucial component for businesses looking to navigate the complexities of sourcing. With an ever-growing number of companies relying on suppliers and manufacturers in this dynamic market, understanding the nuances of Supplier & Factory Audit processes is essential. These audits not only ensure compliance with industry standards but also play a pivotal role in establishing trust between businesses and their partners.

Importance of Factory Audit Services in China

Factory audit services in China are vital for ensuring that suppliers meet quality control standards and adhere to regulatory requirements. As companies expand their operations globally, they often encounter various challenges regarding transparency and reliability within their supply chains. By investing in thorough Factory Audits & Supplier Audits in China, businesses can mitigate risks associated with poor quality products or unethical practices.

Understanding Supplier and Factory Audits

Understanding the differences between supplier audits and factory audits is key to effective risk management. While supplier audits generally focus on evaluating a company's overall capabilities, factory audits delve deeper into specific manufacturing processes, equipment conditions, and workforce compliance with safety regulations. This distinction is particularly important when asking yourself, How do I verify a factory in China?—as both types of audits provide valuable insights into potential partnerships.

The Role of Legal Verification

Legal verification serves as a backbone for ensuring that factory audit services comply with local laws and international standards. In China, where regulatory landscapes can shift rapidly, knowing What are the audit requirements in China? is essential for any business looking to establish reliable operations. Furthermore, understanding whether Do Chinese companies have to be audited? can help organizations navigate legal obligations effectively while fostering stronger relationships within their supply chains.

Why Factory Audits Matter for Your Business

In the dynamic world of global trade, factory audit services in China are not just a luxury; they are a necessity. Supplier & factory audits play a crucial role in ensuring that businesses maintain high standards of quality and compliance. By implementing effective factory audits & supplier audits in China, companies can safeguard their reputation and streamline their operations.

Ensuring Quality Control and Compliance

Quality control is the backbone of any successful business relationship, especially when dealing with suppliers overseas. Factory audit services in China help ensure that products meet both local and international standards, reducing the chances of costly recalls or compliance issues. When you ask yourself, “What are the audit requirements in China?” remember that these audits provide a comprehensive assessment of your supplier’s capabilities to deliver quality goods consistently.

Reducing Risks in Supply Chain Management

Navigating the complexities of supply chains can be daunting, but factory audits significantly mitigate risks associated with sourcing from Chinese manufacturers. By conducting thorough assessments, businesses can identify potential pitfalls early on—whether it’s financial instability or subpar production practices—which helps prevent disruptions down the line. In essence, understanding “How do I verify a factory in China?” becomes easier when you leverage robust auditing processes to fortify your supply chain.

Building Trust with Your Suppliers

Trust is essential in any business relationship, particularly when working with suppliers across borders. Engaging in regular factory audits fosters transparency and accountability between parties involved; it shows that you’re serious about maintaining high standards while also valuing their efforts to comply with regulations. Moreover, when you ask “Do Chinese companies have to be audited?” the answer often lies within building this trust—demonstrating commitment to legal verification and ethical practices encourages long-term partnerships that benefit everyone involved.

Navigating Audit Requirements in China

Understanding the maze of audit requirements in China is crucial for businesses aiming to maintain compliance and quality control. Factory audit services in China are not just about ticking boxes; they involve intricate regulations that govern how Supplier & Factory Audits are conducted. Knowing what these requirements entail can save you time, money, and potential legal headaches down the road.

Overview of What Are the Audit Requirements in China

What are the audit requirements in China? These requirements vary depending on industry standards, local laws, and international trade agreements. Generally speaking, audits must assess quality management systems, labor practices, environmental compliance, and financial integrity to ensure that factories adhere to both local and international standards.

Factory Audits & Supplier Audits in China often require documentation such as business licenses, tax records, and safety certifications. Notably, Chinese companies are increasingly subject to audits as part of their commitment to transparency and quality assurance. This shift means that businesses looking to partner with Chinese suppliers need to be well-versed in these evolving audit expectations.

Key Regulations Impacting Factory Audits

The General Administration of Quality Supervision, Inspection and Quarantine (AQSIQ) establishes guidelines that many factories must follow regarding product safety and quality assurance processes. Additionally, regulations like ISO 9001 provide a framework for quality management systems that many suppliers strive to meet.

It's essential for businesses engaging with Chinese manufacturers to familiarize themselves with these regulations as they directly affect compliance during Supplier & Factory Audits. Furthermore, understanding whether Do Chinese companies have to be audited can clarify your expectations when selecting a supplier or manufacturer for your products. Proper knowledge of these regulations can also help mitigate risks associated with supply chain disruptions.

Understanding the Legal Landscape with AC&E

Navigating the legal landscape concerning factory audits involves understanding both domestic laws and international trade agreements impacting your business operations in China. Legal verification processes play a critical role here; they ensure that all necessary documentation is accurate and compliant with local laws before proceeding with any supplier engagement or contract signing.

AC&E (Audit Compliance & Enforcement) serves as an essential framework guiding businesses through this complex environment by providing resources on factory audit services in China tailored specifically for foreign enterprises. By leveraging AC&E’s insights into regulatory changes and compliance strategies during Supplier & Factory Audits, you can better position your company for success while minimizing legal risks associated with non-compliance.

In summary, being aware of what happens in a factory audit is vital for any business seeking partnerships within China's vast manufacturing landscape. As you consider how do I verify a factory in China?, remember that thorough knowledge of audit requirements will empower you not only to choose reliable suppliers but also foster long-term relationships built on trust and accountability.

The Factory Audit Process Explained

Navigating the factory audit process can feel like traversing a maze, especially when dealing with the unique landscape of factory audit services in China. Understanding what happens during a factory audit is essential for businesses looking to establish reliable supplier relationships and ensure compliance with local regulations. This section will unpack the various components of the factory audit process, providing clarity on steps involved and effective techniques for conducting audits.

What Happens in a Factory Audit?

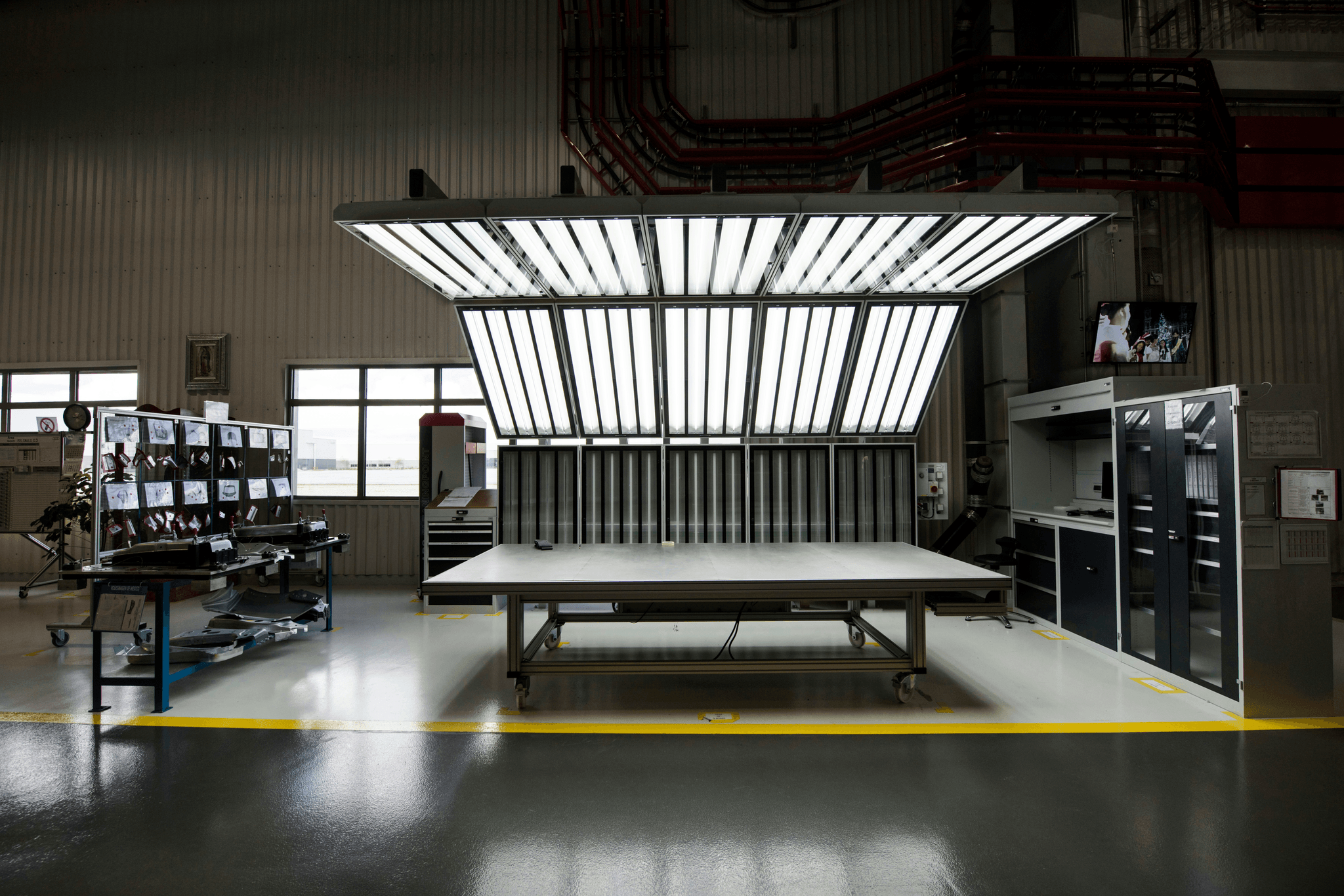

A factory audit is not just a checklist exercise; it’s an in-depth examination of a supplier's operations, quality control measures, and compliance with legal requirements. During a typical audit, auditors will assess everything from production processes to labor conditions while verifying that suppliers meet specific standards. The goal is to ensure that your potential partners are not only capable but also compliant with both local laws and your business requirements.

Steps Involved in Conducting Audits

Conducting a Supplier & Factory Audit involves several critical steps that help ensure thoroughness and accuracy. First, auditors typically prepare by reviewing documentation related to what are the audit requirements in China, including relevant regulations and standards applicable to the industry. Next comes the on-site evaluation where auditors observe operations firsthand, interview staff, and review records—this phase is crucial for identifying any discrepancies or areas needing improvement.

After gathering data during the site visit, auditors compile their findings into a comprehensive report outlining strengths, weaknesses, and recommendations for improvement. This report serves as an essential tool for businesses asking themselves: “How do I verify a factory in China?” It provides insights into whether potential suppliers can meet your expectations.

Techniques for Effective Auditing

To maximize the effectiveness of Factory Audits & Supplier Audits in China, employing specific techniques can make all the difference. One effective method is using checklists tailored to local regulations; this ensures that no stone goes unturned when assessing compliance with legal verification standards. Additionally, fostering open communication during interviews can help uncover valuable insights about operational practices that may not be immediately apparent through observation alone.

Another technique worth considering is leveraging technology—digital tools can streamline data collection and analysis processes during audits while ensuring accuracy throughout each phase of evaluation. By implementing these strategies within your auditing framework, you’ll enhance your ability to identify risks early on while building trust with your suppliers.

How Do I Verify a Factory in China?

Verifying a factory in China is crucial for businesses looking to establish reliable supply chains. The process involves several strategies and tools designed to ensure that suppliers meet quality standards and comply with regulations. Understanding how to effectively navigate this landscape can save you time, money, and potential headaches down the line.

Strategies for Factory Verification

When it comes to verifying a factory, having a robust strategy is essential. Start by conducting thorough research on the factory’s background, including its history, ownership structure, and any previous audit reports. This foundational knowledge will help you assess whether the factory aligns with your company’s values and standards.

Additionally, consider visiting the factory in person if possible; nothing beats firsthand experience when it comes to understanding what happens in a factory audit. During your visit, observe not only the production processes but also employee conditions and safety measures in place. These elements are crucial indicators of a supplier's reliability and commitment to quality.

Finally, leverage technology by utilizing online platforms that provide insights into factory operations and customer feedback. These resources can give you an idea of how other companies have fared with their suppliers through Factory Audits & Supplier Audits in China.

Utilizing Third-Party Audit Services

Engaging third-party audit services can significantly enhance your verification process when asking yourself: How do I verify a factory in China? These independent auditors bring expertise and objectivity that internal teams may lack, ensuring compliance with local regulations as well as international standards.

Third-party services typically conduct comprehensive assessments that include legal verification aspects—examining documentation related to business licenses, certifications, and compliance records. This level of scrutiny helps mitigate risks associated with misrepresentation or inadequate practices within factories.

Moreover, these audits often cover key areas such as labor practices, environmental impact, and product quality control measures—essential factors for maintaining trust with your suppliers while ensuring you’re meeting What are the audit requirements in China? By relying on experienced auditors who understand local nuances and expectations, businesses can confidently move forward in their partnerships.

Assessing Supplier Capabilities

Once you've verified the existence of a potential supplier through various strategies or third-party audits, it's time to assess their capabilities more closely. Start by evaluating their production capacity; this includes understanding lead times for orders as well as flexibility during peak seasons or unexpected demand spikes.

Next up is examining the technology used within the facility—are they equipped with modern machinery? This plays a significant role not only in efficiency but also impacts product quality directly during Factory Audits & Supplier Audits in China processes.

Lastly, don’t underestimate the importance of communication during this assessment phase; clear channels help foster transparency between both parties involved. Regular updates about production status or any issues encountered can build trust over time while ensuring everyone stays aligned on expectations—an essential component when questioning: Do Chinese companies have to be audited?

Common Challenges in Factory Audits in China

Conducting factory audits in China can be a daunting task, fraught with challenges that can complicate the process. From misrepresentation to cultural nuances, understanding these obstacles is crucial for businesses seeking reliable factory audit services in China. This section delves into some of the most common challenges faced during supplier and factory audits in this dynamic market.

Misrepresentation and Transparency Issues

One of the primary hurdles when engaging in factory audits and supplier audits in China is the issue of misrepresentation. Suppliers may present inflated capabilities or falsified documentation to impress potential clients, leading to significant discrepancies between reported and actual conditions. This lack of transparency can undermine trust and complicate compliance with what are the audit requirements in China, making thorough legal verification essential.

When asking How do I verify a factory in China?, it’s vital to employ comprehensive auditing techniques that go beyond surface-level assessments. Engaging third-party audit services can help mitigate these risks by providing an unbiased perspective on the supplier's operations. By ensuring that transparency is prioritized throughout the audit process, businesses can protect themselves from costly surprises down the line.

Cultural Differences Impacting Audits

Cultural differences play a significant role during factory audits and can affect communication and expectations between auditors and Chinese suppliers. Understanding local customs, business practices, and negotiation styles is essential for successful engagement during supplier & factory audits in China. These cultural nuances may lead to misunderstandings if not addressed properly, potentially skewing audit results.

Moreover, attitudes toward authority and hierarchy may influence how information is shared during an audit. For instance, employees might hesitate to voice concerns or provide honest feedback due to fear of repercussions within their organization. Therefore, being culturally aware is crucial for auditors aiming to create an open environment where genuine dialogue can occur.

Overcoming Communication Barriers

Effective communication is paramount when conducting factory audits; however, language barriers often pose significant challenges for international auditors operating in China. Misinterpretations or lack of clarity can lead to incomplete assessments regarding what happens in a factory audit or even obscure critical issues affecting compliance with local regulations.

To overcome these communication barriers during supplier & factory audits in China, it's advisable to work with bilingual auditors who understand both English and Mandarin fluently. Additionally, utilizing visual aids or translated documentation can facilitate clearer exchanges between parties involved in the auditing process. Ultimately, investing time into establishing effective lines of communication will enhance overall auditing outcomes while fostering better relationships with suppliers.

Conclusion

In the ever-evolving landscape of global trade, factory audit services in China have become indispensable for businesses seeking reliable suppliers. Understanding the nuances of Supplier & Factory Audits is crucial to ensure compliance and quality control. As companies navigate this complex environment, they must remain vigilant about legal verification to safeguard their interests.

Best Practices for Factory Audits in China

To maximize the effectiveness of factory audits & supplier audits in China, businesses should adopt a systematic approach. First, it's essential to familiarize oneself with what are the audit requirements in China, as these can vary significantly based on industry and region. Additionally, conducting thorough pre-audit assessments can help identify potential red flags before diving into what happens in a factory audit.

Another best practice involves engaging experienced auditors who understand local regulations and cultural nuances. This expertise can mitigate challenges such as misrepresentation and transparency issues that often arise during audits. Finally, maintaining open lines of communication with suppliers fosters trust and encourages a more transparent auditing process.

Leveraging Audit Services for Business Growth

Factory audit services in China not only ensure compliance but also serve as a springboard for business growth. By verifying supplier capabilities through rigorous audits, companies can confidently expand their operations while minimizing risks associated with supply chain management. This proactive approach allows businesses to build strong relationships with trustworthy suppliers who meet quality standards.

Moreover, leveraging third-party audit services enables companies to focus on core business functions while experts handle the complexities of supplier evaluations. As organizations discover how do I verify a factory in China effectively, they gain valuable insights that inform strategic decisions and drive operational efficiencies. Ultimately, investing in robust factory audits translates into enhanced reputation and customer satisfaction.

The Future of Factory Audits and Compliance

Looking ahead, the future of factory audits and compliance will likely be shaped by technological advancements and evolving regulatory landscapes. With increasing scrutiny on supply chains globally, do Chinese companies have to be audited more frequently? The answer is likely yes; as compliance becomes more critical than ever, regular audits will be essential to maintain market access.

Additionally, integrating digital tools into the auditing process can streamline operations and improve data accuracy during evaluations. As businesses continue to evolve their strategies around legal verification within this framework, staying informed about key regulations impacting factory audits will be paramount for success moving forward.